- Volvo Penta

- Starter motors Volvo Penta

- Sensors Volvo Penta

- Valve covers – oil sumps Volvo Penta

- Wiring harnesses Volvo Penta

- Gearboxes – saildrives Volvo Penta

- Fuel systems Volvo Penta

- Instrument panels Volvo Penta

- Pistons – connecting rods Volvo Penta

- Cooling water system Volvo Penta

- Crankshafts – camshafts Volvo Penta

- Flywheels – flywheel housings Volvo Penta

- Cylinder heads Volvo Penta

- Heat exchangers and aftercoolers Volvo Penta

- Alternators Volvo Penta

- Control units / EVC / MDI Volvo Penta

- Exhaust systems Volvo Penta

- Engine lubrication system Volvo Penta

- Aftermarket Volvo Penta

- Saildrives Volvo Penta

- Engine mounts Volvo Penta

- Vetus

- Yanmar

- Ellebogen

How to Replace an Impeller

Replacing an impeller is a vital part of boat maintenance. Thankfully, it’s often straightforward.

Why is an Impeller Important?

The impeller, a flexible rubber component, circulates cooling water to prevent engine overheating. Regular checks and timely replacement are crucial to avoid engine damage.

When Should You Replace It?

Replace the impeller every year or after 100–200 operating hours, especially in salt or dirty water. Look for signs of wear like missing rubber pieces or swelling due to chemical reactions.

Regular maintenance ensures safe and efficient engine performance!

Common Impeller Issues

-

Worn Blades: Reduced water flow and inconsistent cooling.

-

Broken Impeller: Can cause serious engine damage due to blockages.

-

Incorrect Installation: Ensure the correct rotation direction.

Regular maintenance is key to extending engine life and avoiding costly repairs!

Step-by-Step Guide: Replacing an Impeller

-

Close the Water Valve: Prevent water from entering the engine during replacement.

-

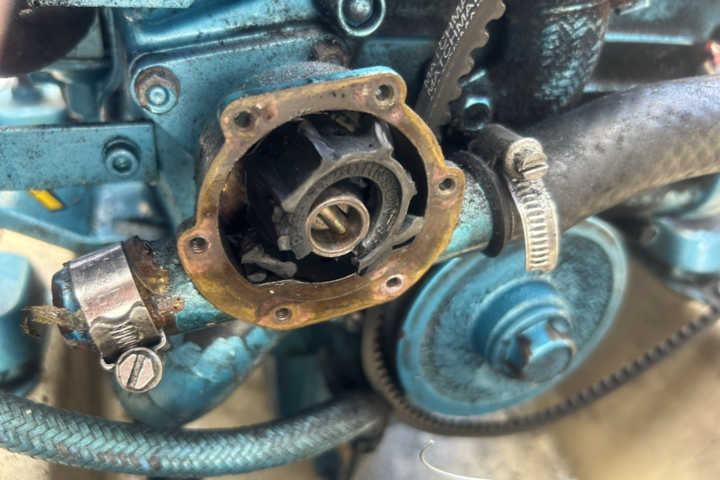

Locate the Pump Housing: Usually at the front of the motor; follow cooling system hoses if needed.

-

Open the Housing: Unscrew the cover, expect some water, and carefully remove the gasket.

-

Remove the Old Impeller: Note the rotation direction and use a puller or pliers to avoid damage.

-

Inspect for Debris: Remove rubber remnants to prevent clogs.

-

Install the New Impeller: Lubricate with petroleum jelly, align properly, and grease the housing.

-

Reassemble: Replace the gasket and screw the housing tightly.

-

Test the System: Open the valve, start the engine, and check for water flow from the exhaust.

Choosing the Right Impeller

-

Identify your pump’s brand and model number.

-

Select materials based on use:

-

Neoprene: For fresh or saltwater cooling.

-

Nitrile: For bilge pumps and oily or polluted water.

-

Polyurethane: For ballast pumps in intensive applications.

Order genuine impellers from Marinepartsystem for quality and reliability. Contact us for expert advice!